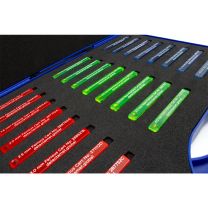

Metal Detector Test Pieces

Metal detectors play a crucial role in the food industry, primarily contributing to food safety and quality assurance. They are used to detect and remove metal contaminants from food products during processing and packaging, thereby preventing potential harm to consumers and ensuring compliance with food safety regulations. Click to read more...

- Consumer Safety: The primary reason for using metal detectors in the food industry is to ensure consumer safety. Metal fragments can enter food products through various stages of production, packaging, or transportation. Detecting and removing these contaminants helps prevent injuries, choking hazards, or other health risks to consumers.

- Quality Assurance: Food companies use metal detectors to maintain high-quality standards. Finding and removing metal contaminants before products reach consumers helps maintain a company's reputation for quality and safety.

- Regulatory Compliance: Food safety regulations, like those set by the FDA, USDA, and other international agencies, often require food manufacturers to have contamination prevention measures in place. Metal detectors help companies comply with these regulations, reducing the risk of fines, recalls, or shutdowns.

- Cost Savings: Detecting metal contaminants early in the production process can prevent costly recalls, production downtime, or damage to machinery. This can lead to significant cost savings for food manufacturers.

- Product Integrity: Metal contamination can affect the integrity and appearance of food products, leading to customer dissatisfaction and returns. Using metal detectors ensures that the final products meet the expected standards.

- Reduced Risk of Legal Action: If a consumer is harmed by a contaminated product, the company could face lawsuits or other legal actions. Metal detectors reduce this risk by minimizing the chances of contaminated products reaching consumers.

- Customizable and Versatile: Metal detectors in the food industry can be customized to fit various production lines, detecting a wide range of metals (ferrous, non-ferrous, and stainless steel). This flexibility allows them to be used across different food sectors, including bakery, dairy, meat, poultry, seafood, and packaged foods.

- Promoting Customer Trust: Consumers trust food companies to provide safe products. By implementing metal detection systems, companies demonstrate their commitment to safety and quality, enhancing customer trust and loyalty.

Metal detectors are essential in the food industry because they ensure safety, comply with regulations, reduce costs, and maintain product quality. They are a key component of a robust food safety and quality assurance program.

Metal detectors play a crucial role in the food industry, primarily contributing to food safety and quality assurance. They are used to detect and remove metal contaminants from food products during processing and packaging, thereby preventing potential harm to consumers and ensuring compliance with food safety regulations.

- Consumer Safety: The primary reason for using metal detectors in the food industry is to ensure consumer safety. Metal fragments can enter food products through various stages of production, packaging, or transportation. Detecting and removing these contaminants helps prevent injuries, choking hazards, or other health risks to consumers.

- Quality Assurance: Food companies use metal detectors to maintain high-quality standards. Finding and removing metal contaminants before products reach consumers helps maintain a company's reputation for quality and safety.

- Regulatory Compliance: Food safety regulations, like those set by the FDA, USDA, and other international agencies, often require food manufacturers to have contamination prevention measures in place. Metal detectors help companies comply with these regulations, reducing the risk of fines, recalls, or shutdowns.

- Cost Savings: Detecting metal contaminants early in the production process can prevent costly recalls, production downtime, or damage to machinery. This can lead to significant cost savings for food manufacturers.

- Product Integrity: Metal contamination can affect the integrity and appearance of food products, leading to customer dissatisfaction and returns. Using metal detectors ensures that the final products meet the expected standards.

- Reduced Risk of Legal Action: If a consumer is harmed by a contaminated product, the company could face lawsuits or other legal actions. Metal detectors reduce this risk by minimizing the chances of contaminated products reaching consumers.

- Customizable and Versatile: Metal detectors in the food industry can be customized to fit various production lines, detecting a wide range of metals (ferrous, non-ferrous, and stainless steel). This flexibility allows them to be used across different food sectors, including bakery, dairy, meat, poultry, seafood, and packaged foods.

- Promoting Customer Trust: Consumers trust food companies to provide safe products. By implementing metal detection systems, companies demonstrate their commitment to safety and quality, enhancing customer trust and loyalty.

Metal detectors are essential in the food industry because they ensure safety, comply with regulations, reduce costs, and maintain product quality. They are a key component of a robust food safety and quality assurance program.

Detectamet Canada (English - $ CAD ) Click here to change your currency, region and language.

Detectamet Canada (English - $ CAD ) Click here to change your currency, region and language.